Can I use gradients of colour or full colour print for my enamel badge?

29 Aug 2018

In the world of lapel badges, almost anything is possible. The trick is matching the design requirement to the perfect choice of badge.

Certain designs lend themselves naturally to certain methods of production, but there are often imaginative solutions to design problems that can help you achieve the effect you need.

Let's begin with the basic question though - can gradients of colour be included in an enamel badge?

For a true and unembellished enamel badge, the answer is 'no'. There is no actual 'printing' involved with making an enamel badge. Instead the colour comes from 'enamelling' - and enamel can only be applied in solid colour blocks, with each area of colour being bounded by a fine line of metal.

This is due to the production process, whereby the design is struck into metal, creating areas of raised and recessed metal. The recessed areas are then available for the infill of coloured enamel in liquid form, which is then hardened. This also means that the coloured areas need to have a certain thickness to them in order for the colour to fill. If a line is extremely fine, it will be better to form the line in metal rather than trying to colour fill a delicate path that would need to be surrounded by metal.

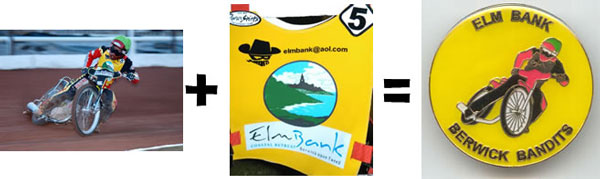

The image below shows a true enamel badge, where every colour area is a single continuous colour block that is surrounded by a fine line of silver metal:

But for those who have a full colour or gradient logo that is not the end of the story. There are three common options available, and our advisors are experienced in helping with each of choices.

Option 1) Adjust The Artwork

Our free artwork service can help adjust your logo for enamelling. We can show you a design idea that will work in metal and enamel, with clear explanation of the design adjustments made. Many organisations maintain versions of both a full colour logo and a spot colour logo, and it may be that you find that the adjusted artwork is exactly what you need.

Option 2) Switch to a Printed Badge

For a particularly complicated design, we often recommend switching to a 'Printed Metal Badge' instead of a true enamelled badge. A printed metal badge (as the name suggests) sees your design printed exactly as supplied to a metal base. The print can either be a full colour CMYK print, or spot colours matched to pantones.

In either case the badge itself is still cut to an entirely bespoke shape, and fitted with the same choice of attachments. The feel is usually slightly lighter than with an enamel badge (an advantage if the badge size is large, less so if the badge size is small) because the base metal of steel or aluminium is lighter than the brass, copper or iron base metals used for enamel badges.

Option 3) Overprint to Enamel

A final option available is a hybrid of enamelling and printing. In this case we make an enamel badge by the traditional method, but then use overprinting processes to add detail that would otherwise be impossible to include.

The overprinted elements can be a significant part or the whole of the design, or they can be limited to specific small details. For example, a common need is for different numbers to be printed to years of service badges. The changing numbers are printed while all other details are enamelled.

Whatever your logo requirement, a design solution is waiting somewhere.